Light Gauge Steel Frame Technology [LGSF] is a modern, fast & efficient Construction Technology that is getting more and more popular.In this of technology Highly Quality, High Tensile, Galvanised Steel members are used as the skeletal structures of the entire building, including Wall panels, Floor Joists and Roof Trusses.LGSF structure construction is a quick and easy solution for single to multi-storey buildings.The concept of standardised light framed residential buildings is to build more buildings in a short period with fewer resources. One of the main advantages of light steel framing is its versatility and the range of building types for which it can be used.

Stratus Steel is one of the top light gauge steel framing manufacturers in India providing a complete solution right from planning, designing, manufacturing to site installation. The use of LGSF technology provides ease of installation along with a reduction in the cumulative project completion period owing to prefabricated steel structures. Applications of light steel framing range from low-rise housing to multi-storey, multi-occupancy developments, including panelised structural frames, external infill walling systems and fully finished offsite / onsite modular construction.

The wide range of applications is in addition to the benefits one would expect with a modern construction method: rapid speed of construction, high quality and performance, excellent safety and cost-effectiveness. A major sector for light steel framing is four to eight-storey residential buildings and mixed-use buildings often comprising Hospitals, commercial space and car parking at the lower levels. In these cases, the lightweight characteristic of the construction system is crucial to minimizing the loads on the supporting structure.

Stratus Steel Light Gauge Steel Framing

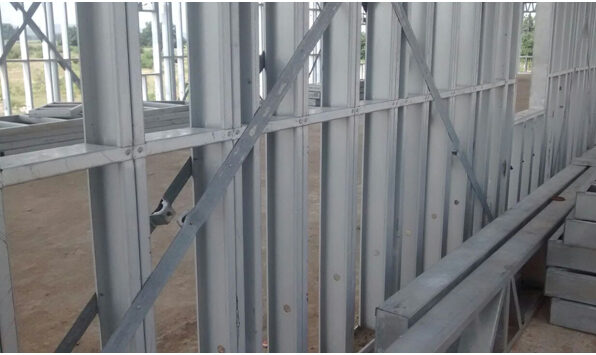

Light steel framing comprises galvanized cold-formed C sections of 89mm to 150mm depth in the wall panels, and 150mm to 300mm deep C sections or lattice joists in the floors. Spans of up to 6m-9m can be achieved, which can eliminate internal load-bearing walls and therefore leads to flexibility in internal space planning.

The prefabricated wall panels are typically storey-height (ie 2.7m to 3.2m) and up to 8m long, depending on transportation and lifting.

A house can be constructed from as little as 12 wall panels and up to four houses or large apartments can be delivered per truck. The floors can be installed in the form of prefabricated floor cassettes, or as individual joists.

The option to use composite floor slabs supported by the light steel walls is popular. In this case, the floor slab is typically 150mm to 300mm deep using profiled steel decking with in-situ concrete and spans up to 5.5m when propped temporarily during construction. Not only is the self-weight half of that of a concrete flat slab but it is shallower and provides for routing of ducts suspended from the decking.

What We Offer

With the scope this technology presents, Stratus Steel makes sure you benefit from each bit of it!

Both joisted and composite floors often use slim floor beams that are integrated within the floor zone to create more open plan space, which is particularly useful in care homes and in lobby areas. Concrete and steel stairs are generally delivered as part of the light steel package and are integrated into the Building Information Model (BIM) or the structural design.

The structural performance of cold-formed sections enables their use in a wide variety of applications. A light steel C section of only 1.5mm thickness can support up to 50kN in compression. Structural bracing is integrated into the walls for stability so that medium-rise buildings do not require additional cores. Efficient design solutions are achieved by selecting the steel thickness and configuration of sections to suit the specific loading conditions.