History of CFS (Cold-formed steel) a.k.a LGSF (Light Gauge Steel Framing)

Did you know that cold-formed steel framing has been used as a building material since the 1800s? Then, however, it was in forms and proportions very different from those seen today.

Cold-formed steel framing was first used to construct buildings in the 1850s in both the US and Britain. The use was mainly exploratory and restricted to a few fundamental structures.

If you work in the construction business, you may know about cold-formed steel framing. So let’s look at how this framing choice came to be.

What Is Cold-Formed Steel Framing?

Cold-formed steel (CFS) is a fabrication technique. The technique involves the roll-forming of metallic covered sheet steel through a series of dies, into many components such as:

• Studs

• Joists

• Tracks

• Headers

• Angles

• Truss members

Unlike hot-rolled steel, cold-formed steel does not require heat to create the forms, hence the name. In addition, steel is available in a range of thicknesses to suit a wide variety of structural and non-structural uses.

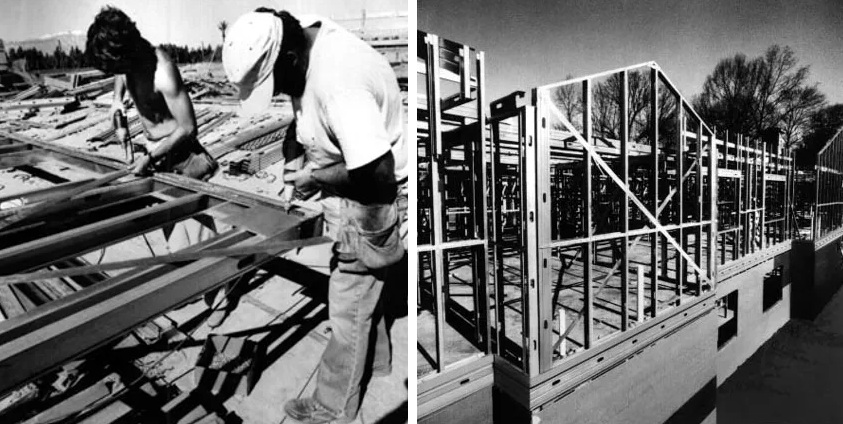

Cold-Formed Steel History

Cold-formed steel as a building material dates all the way back to the 1800s. Corrugated iron manufacturers first used mild steel in the 1890s. Mild steel became an excellent sheathing and structural cladding material in construction.

A recognizable type of CFS framing emerged in the early 20th century. That most likely was to imitate the shaped wood studs popular for construction.

There are a few speculative claims about who constructed the first building using CFS. It seems, however, that the earliest recorded usage is the building of the Virginia Baptist Hospital in 1925 in Lynchburg.

Cold-formed steel made its official premiere at the World’s Fair in Chicago in 1933. Three houses were constructed in this exhibit area. They all made significant use of cold-formed shapers or were entirely framed in steel.

These included:

• The General House home

• The Armco-Ferro House

• The Stran-Steel House

In February 1939, the American Iron and Steel Institute’s Committee on Building Codes funded a research study at Cornell University. This research led to the 1946 release of the AISI’s “Specification for the Design of Light Gauge Steel Structural Members.”

The Post-War Economic Boom

Following World War II, several nations worldwide had a housing shortage during the early postwar period. Hundreds of thousands of houses and commercial structures were destroyed as a result of the war. Furthermore, nations were faced with a large number of returning soldiers from the war.

In the United States, the Lustron Corporation started manufacturing large-scale prefab houses from 1948 to 1950. Several additional methods were also introduced during this period.

The Commercial Market of Cold-Formed Steel Framing

While interest in steel-framed houses fluctuated, CFS gained traction as a popular building material in the US. In the 1950s and 1960s, the building of high rises needed lighter, non-combustible cold-framed steel.

In the 1960s, CFS was used in innovative systems such as curtain walls, external framing with brick veneer, and internal shaft walls.

Cold-formed steel first increased its market share in non-structural uses as in the building of wall partitioning. As of 2004, cold-formed steel framing made up 81% of interior walls constructed in the US.

According to the Steel Framing Industry Association, cold-formed steel structural and nonstructural framing is used to construct between 30% and 35% of all commercial buildings in the US.

To learn more about the use of CFS or LGSF, log on to www.stratus-steel.com or call us at +91 9156551673. You can write to us at work@stratus-steel.com too.