Stratus Steel is one of the pioneers of manufacturing LGSF sections in India. Our in-house FRAMECAD machine produces large-scale cold-formed steel (CFS) construction faster with its advanced steel framing automated process. It further ensures computer-derived calculations for manufacturing LGSF products. All the walls, floor joists, roof truss, etc. are detailed precisely before positioning them in the steel sections. LGSF product is put to test keeping in mind various tests like wind impact, earthquake impact, load-bearing etc.

Our capabilities;

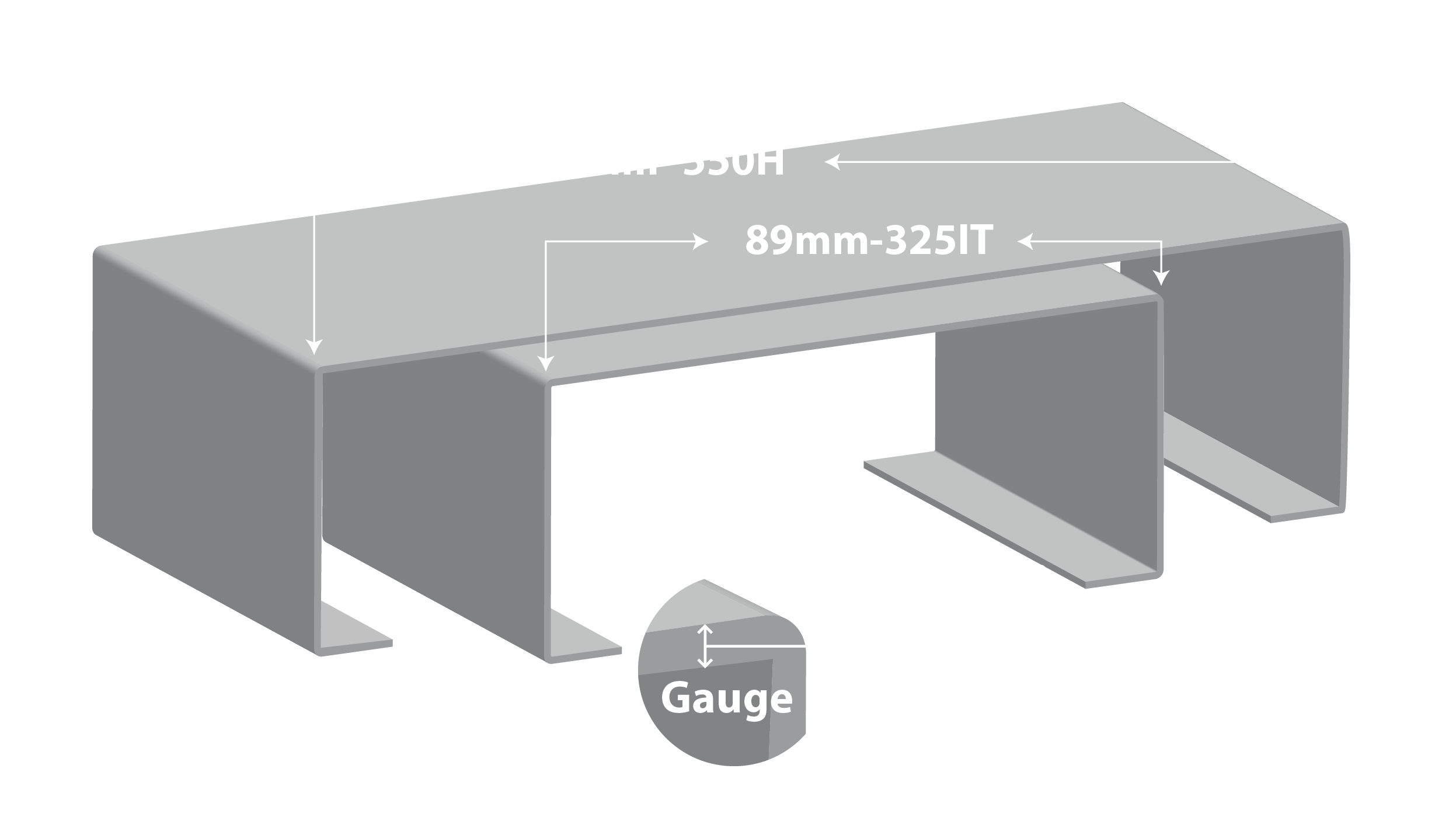

- Roll forming 89mm and 150mm sections using both Galvanized and Galvalume steel coils.

- The specifications that we use for our steel is 550 MPA with a coating of AZ150 for galvalume or 275 GSM for galvanised.

- Strong tie-ups with JSW/ TATA BlueScope help us in giving you the best quality LGSF sections.

Stratus Steel uses LGSF Technology with Higher Grade Of Steel And Galvanization

Galvalume (275 GSM) / Galvanized (AZ 150 GSM Aluminum Zinc Alloy coated steel having minimum yield strength 300- 550 Mpa) conforming to AISI specifications and IBC 2009 for cold formed steel framing and construction and also be ason

Weight in KG per RMT Table of LGSF Steel Profiles:

| Material | Wt. in Kg/mtr |

|---|---|

| 89-0.75 | 1.136 |

| 89-0.80 | 1.121 |

| 89-0.85 | 1.128 |

| 89-0.90 | 1.363 |

| 89-0.95 | 1.439 |

| 89-1.0 | 1.151 |

| 89-1.15 | 1.742 |

| 89-1.2 | 1.818 |

| 150-0.75 | 1.495 |

| 150-0.80 | 1.595 |

| Material | Wt. in Kg/mtr |

|---|---|

| 150-0.85 | 1.694 |

| 150-0.90 | 1.794 |

| 150-0.95 | 1.894 |

| 150-1.0 | 1.994 |

| 150-1.15 | 2.292 |

| 150-1.2 | 2.392 |

| 150-1.5 | 2.29 |

| 150-1.6 | 3.19 |

| 150-2.0 | 3.987 |

Galvanized / Galvalume

550 -300 MPA

89 & 150mm

WHY ARE WE YOUR BEST LGSF MANUFACTURING PARTNERS?

Ready steel stock

Stratus Steel always has a ready stock of mother coils of LGSF in thicknesses ranging from 0.75 to 1.2mm for both 89 and 150mm sections as per the design. Hence, providing a faster turnaround time.

Timely Delivery

Stratus Steel has 3 FrameCad machines thereby ensuring that your timelines are met. With a network of logistics partners across India we offer swift dispatch and efficient delivery.

Value for Money

At Stratus Steel, we lay great emphasis on quality and hence we purchase our steel stock from reputed brands in India. We use the best roll forming machines from FrameCad to manufacture for your project ths enabling us to give you the best product for a competitive price.

Exclusive Partnership Benefits

By partnering with us, you tap into our wealth of knowledge and experience of over 15years. This encompasses marketing, procurement, manufacturing and installation which helps you make your dream project a reality!

WHAT DO WE OFFER?

LGSF Wall panels

STRATUS STEEL MANUFACTURERS BOTH LOAD-BEARING AND NON-LOAD-BEARING WALLS WITH ACCURACY AND PERFECT STRENGTH-TO-WEIGHT RATIO.

- Prefabricated to exact specifications so they can be erected without fuss on-site.

- Quick and efficient LFSG build without any compromise to the structural integrity of the building.

- Service holes are pre-cut and eliminate the need to drill for plumbing and electrical services saving on additional labour costs.

- Termite and borer proof and do not need toxic chemical pest treatments.

LGSF Floors

STRATUS STEEL MANUFACTURES STEEL FLOOR JOISTS COLD ROLL-FORMED C-SECTIONS THAT CAN BE ASSEMBLED EASILY ON-SITE.

- Manufactured to a large span, this allows the number of internal load-bearing walls and columns to be minimised allowing greater flexibility in the design of your building.

- Do not bend and warp over time and can withstand moisture, extreme weather events and pests.

- Offers durability and strength than traditional timber joints.

- A smart, durable and cost-effective flooring solution for your building.

LGSF Roof & Truss

STRATUS STEEL MANUFACTURED ROOF TRUSSES ARE LIGHTWEIGHT AND CAN BE BUILT TO ANY DESIGN USING OUR HIGH-END SOFTWARE AND EQUIPMENT.

- Lightweight makes handling and manoeuvrability onsite easier but they are also rigid, allowing greater spans with less material.

- Additional fire protection as the combustible material within the roof cavity is greatly reduced.

- Manufactured to suit a multitude of roof materials giving you greater scope for the design of your building.

- Recyclable material and therefore offer environmental as well as cost benefits.