Author / admin

-

LGSF-Price Fluctuations

Light gauge steel framing construction (LGSF) is a rapid construction system that is used in cold rolled galvanized steel sections allows us to design and build strong, durable steel-framed buildings easily and efficiently, anywhere in the world. This year, the construction industry has seen price fluctuations like no other. In turn, this scenario has brought…

-

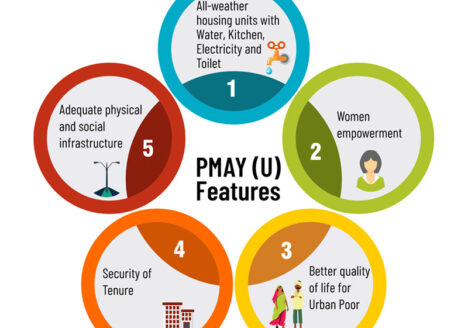

What is the Pradhan Mantri Awas Yojana

Pradhan Mantri Awas Yojana – Urban (PMAY-U), a flagship mission of the Government of India being implemented by the Ministry of Housing and Urban Affairs (MoHUA), was launched on the 25th of June 2015. The Mission addresses urban housing shortage among the EWS/LIG and MIG categories including the slum dwellers by ensuring a pucca house…

-

STRATUS STEEL listed as an LGSF vendor with TATA NEST-IN!

As India surges forward to a smarter time and age, there is a need for newer, innovative and faster construction solutions that will fuel this momentum and make its presence felt in the nation’s growth is Tata Steel Nest-In through its range of steel-based modular construction solutions.Nest-In strives to provide complete turnkey solutions with a…

-

Prefab Construction for Homes

Prefabricated Construction is a process of constructing buildings where components are manufactured separately and transported to the construction site where it is assembled, instead of being manufactured directly at the site. Prefab construction is hardly new. What is new is the idea that this method of construction can be used to revolutionize the entire construction…

-

What is the Significance of LGSF?

Used increasing across the USA, Australia and New Zealand, light gauge steel framing structures are also being heavily introduced in developing countries such as India. With the advancements in technology, the construction is growing and improving progressively. The benefits that come along with the changing technology has encouraged the light gauge steel framing manufacturers in India to pursue and…

-

Stratus Steel: The largest and most equipped LGSF manufacturer in India

The story behind Stratus Steel: The parent group, MGI India since 2000 has successfully endeavored into bringing operating room technology into India and offering its services to the medical industry. As a forward integration to this brand, we branched out into integrating LGSF for the purpose of building FastTrack hospitals. By the year 2008, we…

-

Why Prefabricated Construction using LGSF is the Ideal Choice for Affordable Homes? (Stratus Steel)

What is Prefabricated Construction? Prefabricated Construction is a process of constructing buildings where components are manufactured separately and transported to the construction site where it is assembled, instead of being manufactured directly at the site. Prefab construction is hardly new. What is new is the idea that this method of construction can be used to revolutionize the…

-

How Light Gauge Steel Construction Helped in COVID-19 Pandemic?

The integration of several technologies in the construction sector has always helped enhance the work processes. It has also helped build more sturdier and sustainable buildings that last for a longer duration than ever before. The introduction of LGSF (light gauge steel framing) structures in the construction industry has changed the face of construction choices…

-

Evolution of LGSF Construction in India

Prefabrication is a construction technique where the building is assembled by multiple pieces, manufactured in a factory-controlled environment, and then transported to the construction site for final assembly. In any light gauge steel frame building, structure, or facility, the prefabricated components are designed for every portion separately, including the windows, wall panels, rooftops, and even staircase. For…

-

Why Choose LGSF when planning Rapid Construction?

What might be better for a reasonable customer when an excellent, high-quality structure is offered in comparatively less time while being pocket friendly? All things considered, that isn’t a fantasy anymore. Light gauge steel frame construction has demonstrated to turn all your dreams into a reality. LGSF construction technology offers steel structures that are light in weight…